Energy efficient design is more than just choosing equipment with the highest energy efficiency rating. Real world building operating conditions must be accounted for to ensure energy savings. Energy modeling, not nameplate ratings, is key to specifying equipment that will yield the highest energy and cost savings for a building’s unique operating conditions.

Energy efficiency ratings are not enough

A nameplate’s energy efficiency rating or equipment brochure does not provide enough information to guarantee that level of efficiency in your building. A building is a complex system, made up of many different subsystems, each of which has its own components. There’s heating, ventilation and air conditioning (HVAC), lighting, electrical, and more, all of which have their own control systems and all impact each other. For a building to operate the most efficiently, all the components must work in harmony to maximize equipment efficiency over the whole year, not just during design-day conditions.

Energy modeling reveals hidden energy efficiency

A system component’s design conditions usually drive its energy efficiency rating. However, your building’s normal operating range might fall outside of those design conditions. Operating conditions will determine energy use, so they must be considered. The primary exceptions to this rule are Integrated Energy Efficiency Ratio IEER (formerly SEER), and Integrated Part Load Value (IPLV). These ratings attempt to approximate annual performance through a weighted average of loads and outside air conditions, for packaged cooling and chillers, respectively. But chances are your buildings loads and weather don’t match up perfectly with the assumptions used to calculate the weighted averages.

Using an energy model for the entire operating range of the system to analyze expected energy use is a much better way to tailor your equipment selection to your building and your weather. An energy model will analyze the performance of different pieces of equipment in the system. You can then design/specify equipment around the overall performance. Otherwise, energy efficient design is “in name only”.

Real world energy efficient design success

A few years ago, we used this approach on one of our clients buildings. The project resulted in significant energy savings, that might have remained elusive if we had relied on energy efficiency ratings alone. The project was for a chiller replacement in Utah. Using an energy model, we specified a chiller that had an energy penalty at design conditions. However, the model showed improved performance for all temperature ranges below the design condition.

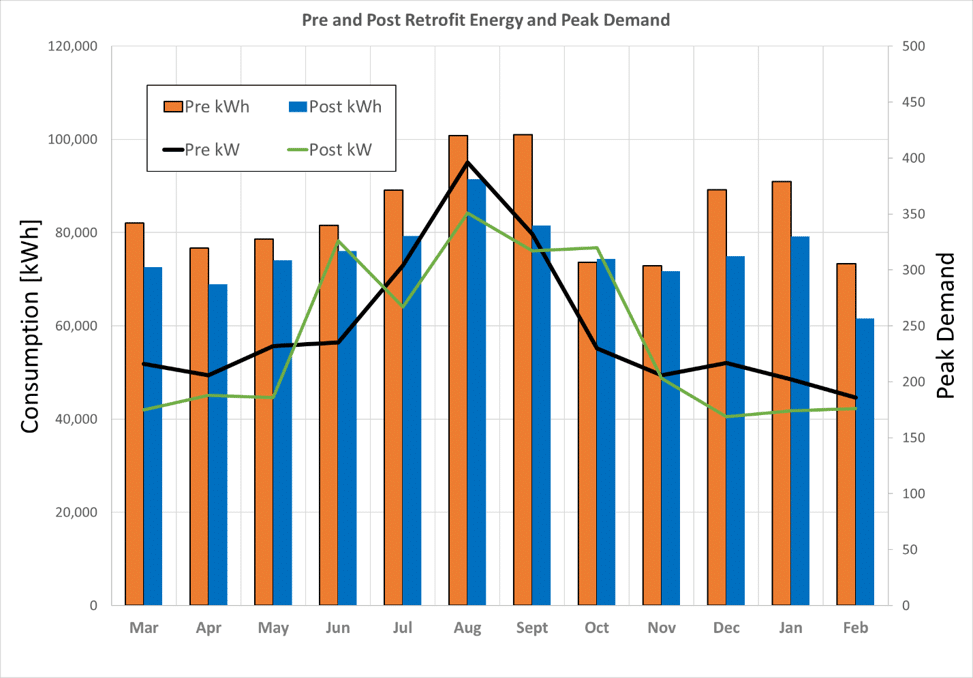

Our client moved forward, choosing our recommended chiller and enjoyed significant energy savings. The chiller replacement reduced annual energy consumption by over 10% and demand by almost 4%. Proof of successful energy efficient is in the performance and billing data. The data from our chiller project is shown in the graph below.

Guarantee energy savings on your next retrofit project

Remember to look beyond the nameplate for your next retrofit project. Energy modeling can be a key element to identifying the best equipment choice for your building – not just for peak conditions, but for the whole year. By taking this extra step, you’ll ensure lower utility bills for years to come. If you need help with your next project or decreasing your building’s energy consumption, contact us.