As efficiency engineers it’s important to be curious, persistent and to get into our client’s shoes.

How, why, and can you show me?

These questions help me remember an ethos that drives me every day as I solve big energy problems. Here is one great success story that resulted from those questions.

We were back on campus as part of a retro-commissioning (RCx) implementation blitz at San Mateo Union High School District (SMUHSD) trying to shed 20% off the District’s energy bills in the current fiscal year. A lofty goal, but I was excitedly optimistic.

The clue: sound of chillers at odd hours

We all suspected the chillers were running at one of SMUSHD’s high schools. The engineers reported hearing them at odd hours. We’d heard them too on a morning RCx scoping visit. Getting those chillers off was my number one priority for the day.

Questions begin

I started with the building engineer: How do you tell if the chillers are running? Can you show me what determines when they’re enabled?

It was related to the various building air handler chiller water valves, but the engineer couldn’t show me exactly. Luckily, we had a controls technician there that day as well.

Questions about controls

Can you show me the code that determines when the plant is enabled?

He pulled it up and the code listed various valves. We confirmed the list with the building engineer and added a few that were missing.

Visualizing control sequences

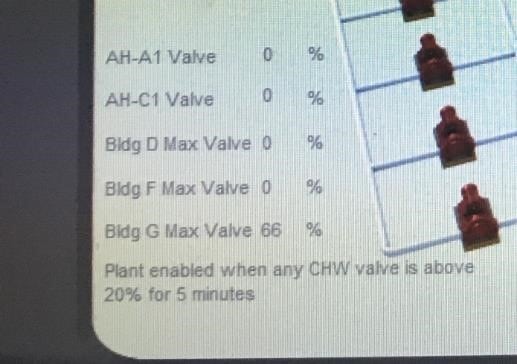

I wanted the building engineer to easily see all the valve positions, so I added a table of them to the main control screen. We also added a time component (5 minutes) and a threshold value (20%) to the enabling call for the plant. I also added a note about the sequence to the control screen as a persistent reminder. In a sense, I was asking the controls screen to show me why the plant is running.

Control screen

Now that we could see how the sequence worked; it was one valve in Building G was keeping the plant on. We chased that lead for a while and ended up making some adjustments to the air handlers; eventually getting the valve to 0%.

Ok, the plant should be off now. The control screen confirms this.

Chiller control screen shows ‘Off’

“Can you show me?” I asked the building engineer. We walked out to the plant.

One chiller was still humming! Wait, what?!

Understanding the unexpected

I asked the controls technician: why does the control screen say it’s off while we can hear it running?

He pulled up the code and we figured out that the ‘Off’ was only the control command but not the actual chiller status.

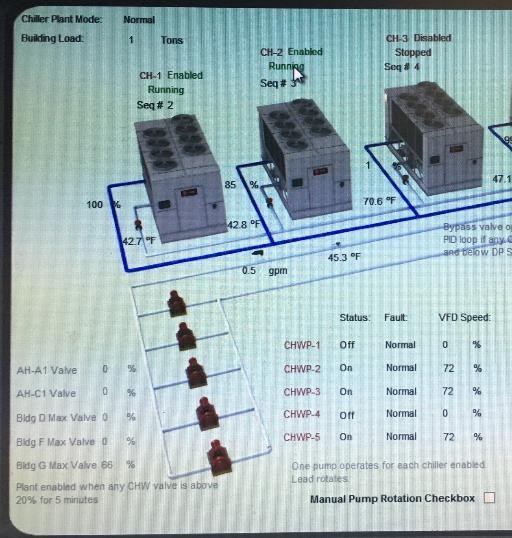

I changed the screen to show both the command and the status and changed the text description and color to be more representative.

Graphic changes and shows ‘Enabled’ for the command and ‘Running’ for the status.

Ok, so now we can see the command is “Disable”, but the status is ‘Running’.

Why? How can this happen?

The District’s controls specialist had an idea and went out to the chillers. He returned 20 minutes later with a small plastic and metal piece and a smirk on this face. It was a jumper that was used to keep the chiller ON during installation, but was left in place (for almost a year!) and never removed.

Savings revealed

Finally, we had found it, the missing piece of the puzzle – a jumper! After it was removed, the chillers were all off. I asked if someone could show me just to be sure.

The pesky cause of inefficient chiller operation, a jumper.

Questions pay off

We left the campus with better scheduling and more intuitive graphics to improve future troubleshooting. This discovery from our RCx efforts contributed to meeting our goal, exceeding 20% cumulative savings over the previous fiscal year. Asking probing questions helped us get there. If you have any questions about your buildings we can dive into and make your building more energy efficient, contact us anytime.

Are you curious about other ways we go undercover in your building? Check out our post on troubleshooting a BAS system at a grocery store.

Like this post? Share it on LinkedIn.