A question from a blog reader about my previous post on phone-based light meters asked what is the difference, if any, between a basic light meter and an LED light meter?

I was a little surprised when my posts about these smart phone apps and purchasing a dedicated light meter gained the traction they did. But the engineering principles were exciting, and hey, I live to make lighting exciting. Let’s dive in about how light meters differ.

How Humans Perceive Light: Light Source Spectra and the Lumen

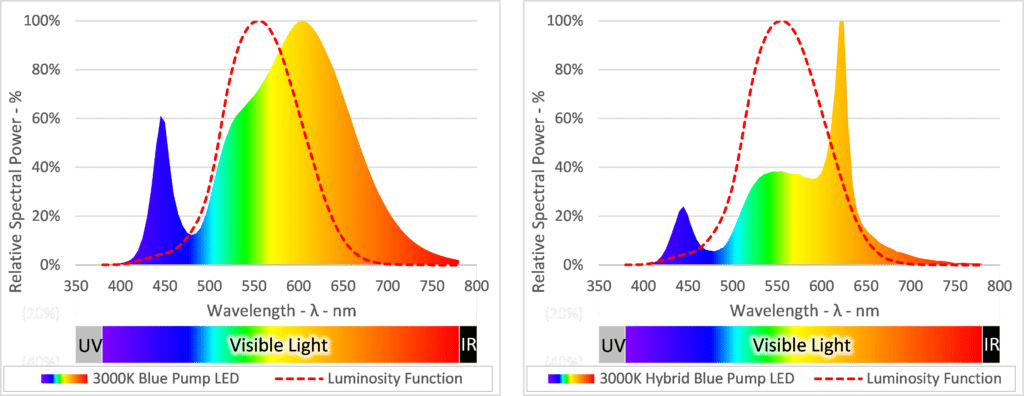

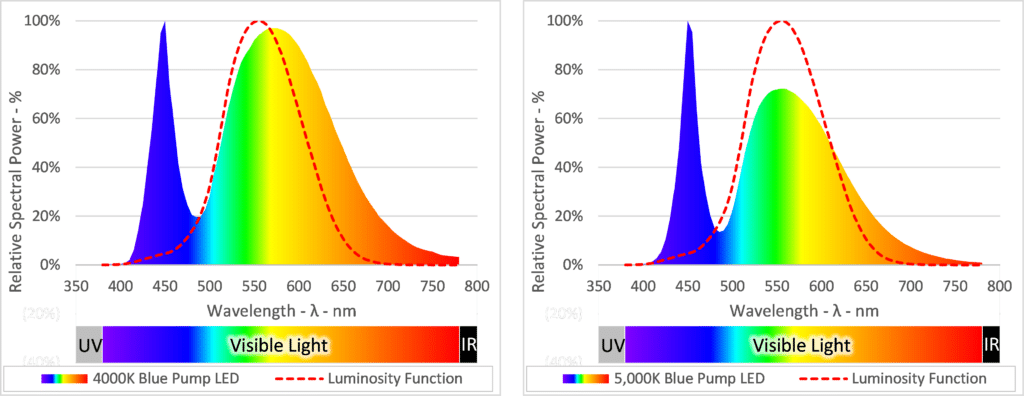

The spectra of light that humans see ranges between about 360 nm (violet) and 780 nm (red). That said, not every wavelength is perceived by people as having the same ‘brightness’ or visual benefit. A room lit with violet or red light would not appear as bright as a space with the same amount (measured in radiative power) of lime-green light.

Now, we need all (or most) of those spectra to render the colors of objects in the same room, but in terms of defining the quantity of perceived light, we need a metric to boil down all that information into a single value. The metric we use, pretty much worldwide, is the photopic weighting function. If we multiply a light source’s emission spectra by that weighting function, we end up the lumen. We then use that lumen combined with other information to calculate intensity, illuminance, exitance, light source efficacy, etc. The lumen is kinda important.

Light Meter Design

Basic light meters – which I’m defining as a light meter that measures illuminance in footcandles or lux and no other metrics – generally rely on one or more different sensors underneath that cosine correction lens. The light meter engineers do what engineers do best and design a cost-optimized meter that measures illuminance to a reasonable degree accuracy. They generally do this by selecting a filter for each sensor with the intent that each sensor will measure all or part of the spectrum accurately. The electronics inside the meter then scale the electrical reading and turn it to an illuminance value we see on the screen.

The F1 factor, or spectrum accuracy, of the meter depends on these engineering decisions and to understand these engineering decisions we need to understand what light sources we were measuring and what price point we are optimizing for.

Entry-Level Light Meters

Inexpensive, entry-level meters designed to measure fluorescent lighting for the most part, could avoid accurately measuring deep blue colors, found with LED lights, since those wavelengths are not typically present in fluorescent spectra. It is not uncommon for light meters to provide a set of correction factors based on the type of light source being measured.

To provide those correction factors, the meter manufacturer would compare the meter detection spectra, typical emission spectra for a lighting technology, and the photopic weighting function. The difference between the product of the emission spectra and the photopic weighting function and the detection spectra and the photopic weight function provides a general correction factor between what the meter will detect under that light source and what the human eye would perceive.

So with older light sources the spectra were predictable between manufacturers – predictable enough that you could provide those correction factors….but then came LEDs.

Measuring LED Light

With LEDs, predictability is not as obvious, given the plethora of LED types out there.

Within each of the LED technologies, the quantity and composition of the phosphor applied to the chip further shifts the emission spectra in predictable ways that are just not feasible to determine in the field. Therefore, a single correction factor isn’t practical with LEDs.

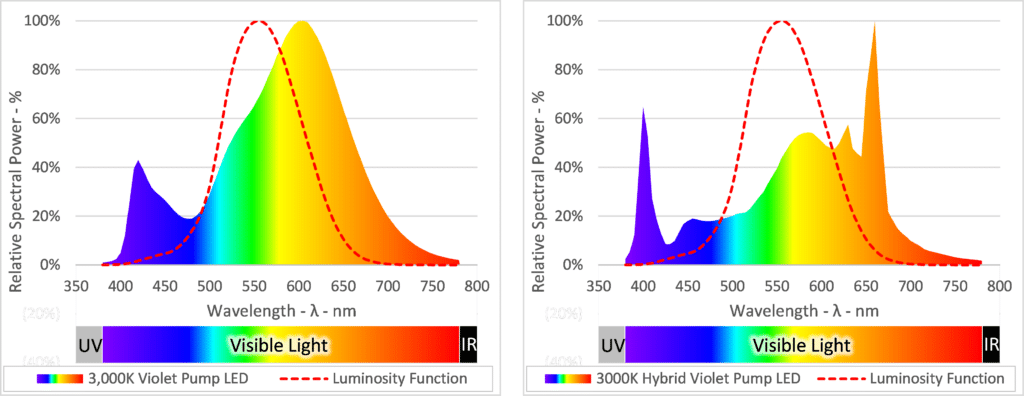

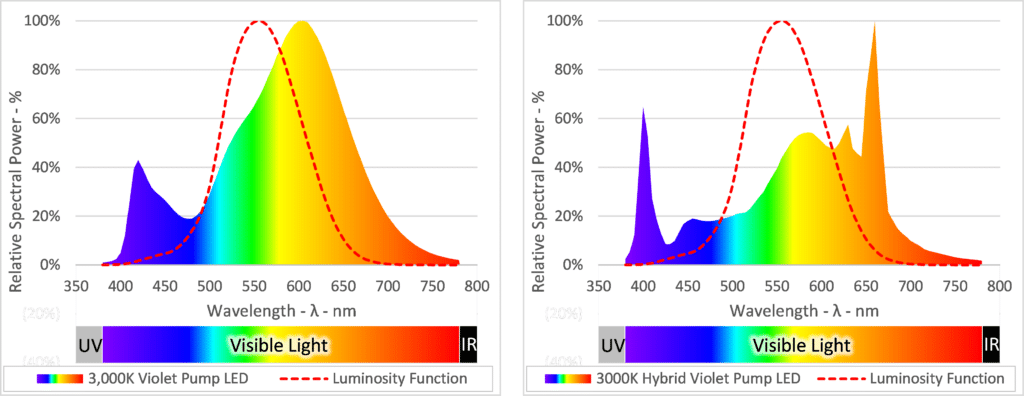

The graphs below demonstrate the shifts in emission spectra from different LED technologies.

1. Blue Pump Phosphor Conversion

2. Violet Pump Phosphor Conversion

3. Color Mixing (RGB, RGBA, etc.)

Light meter manufacturers realize the difficulties in accounting for this in the field. If you look closely at the manufacturer light meter sales literature, they often include a statement about which light sources that specific meter is appropriate for. Today, if you see a light meter that does not explicitly state it’s appropriate for measuring LEDs, you’ll need to dig a little deeper into the specs of that meter or if time is of the essence, consider an alternative meter that claims to support LEDs.

Use the Right Light Meter for the Job

So yes, there is a difference between a basic light meter and an LED light meter. Meters designed for LED measurement are generally more accurate across the spectrum given the wide spectrum variability of LED light sources. Hopefully this exciting dive into spectra, spectrum accuracy and correction factors enlightens your decision the next time you need to take a lighting measurement.

Title image source: xefstock from Getty Images via Canva.com