Supermarkets and their employees now recognized for their essential role in our society, find themselves on the frontlines of the COVID-19 pandemic focused on keeping shelves stocked while trying to maintain social distancing protocols. Refrigeration systems are operating at full capacity due to the unprecedented volume of food moving through grocery stores. With daily news of processing facilities forced to shut down, or reduce production due to a shortage of staff, it is even more important to reduce shrink in supermarkets (for those outside of grocery – “shrink” is product loss due to theft, out of date foods and general losses at the store). Reducing shrink and ensuring refrigeration systems remain operational is critical to ensuring all food makes it to our dinner table!

Importance of Refrigerated Display Case Temperature and Compressor Activity Visibility

Remote monitoring of supermarket refrigeration systems helps ensure product safety and reliable refrigeration system operation. Monitoring refrigerated display case temperatures allow grocers to verify their perishable products are kept within the temperature guidelines specified by the USDA. Monitoring refrigeration compressor operation reveals system activity and energy use, information which can be used to prevent system failure. Through our work in supermarkets, we realized the benefit of remote monitoring and developed a product for this purpose, kW Link.

The kW Link monitors refrigerated case temperatures, compressor activity and provides automated fault detection and diagnostic (AFDD). It connects to the refrigeration control system in one or multiple stores. By tracking operational data from the control system such as case temperatures, suction pressure, discharge pressure, compressor cycling, and more, kW Link can analyze the data with its analytics platform.

Supermarket Refrigeration System Failure Factors

Through data analysis, supermarkets can:

- ensure refrigerated display case temperatures are within acceptable limits from setpoint,

- compressors are not short-cycling, and

- check the ambient split on condensers is not artificially forcing compressors to operate at excessively high discharge pressures.

Monitoring these conditions is essential, as any of these factors can cause a breakdown of the supermarket refrigeration system at a time when, as a society, we cannot afford a loss of food.

Smart Alarms for Refrigerated Display Cases and Compressor Activity

When the kW Link platform detects any of these conditions, it can create an alarm through its AFDD system, which is more sophisticated than basic control system alarms. While basic alarms are set off when limits are exceeded (for example high head pressure), AFDD uses sophisticated logic to create a smart alarm. It looks at operations over time through machine learning and recognizes fault conditions using multiple sensors, inputs, weather, and can employ user-defined logic to elevate issues.

Creating smart alarms helps reduce “alarm fatigue”, the condition where facility operators or equipment technicians ignore alarms due to frequent non-critical alarm events. AFDD system alarms are more selective and highlight what must not be ignored. For more on AFDD vs. faults, see our prior post.

Monitoring Multiple Supermarkets

kW Link also provides means to aggregate data across multiple supermarkets, even with different controller brands in use. By monitoring at multiple stores, you can flag only the stores with issues, saving technician and staff time and increasing the speed of issue resolution.

Additional Benefit of Cost Savings

In addition to reducing shrink, remote monitoring can also help increase profitability through lower electricity bills. Using the same data to optimize system operation, kW Link can save supermarkets money on their energy and peak demand charges by decreasing loads during peak pricing and increasing operational efficiency.

New York State Supermarket Refrigeration Monitoring During COVID-19

We currently have the kW Link installed and connected to numerous stores in New York State. As a result, we monitor compressor activity and energy use before and after the panic surrounding COVID-19 broke out.

Supermarket Refrigeration Compressor Activity Before COVID-19 Panic

The following figure shows the average number of active compressors at one of the stores for the week of March 1, 2020. The average ranges between 1 and 4 compressors during this week.

Impact of COVID-19 Panic Shopping on Refrigeration Systems

Impact of COVID-19 Panic Shopping on Refrigeration Systems

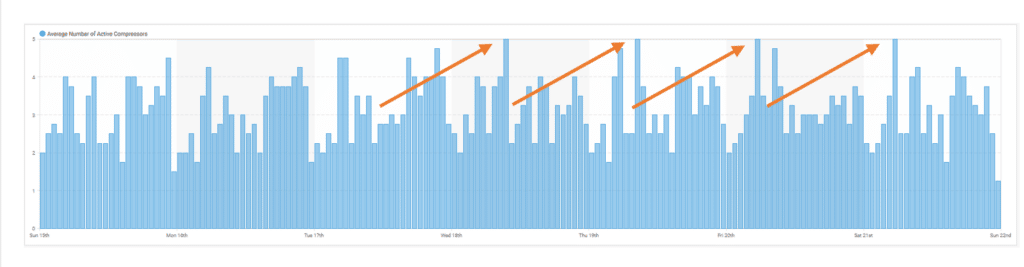

The following figure shows the number of active compressors for the week of March 15th, 2020.

One can see the stress on the compressor rack as ambient temperature crept slightly and panic shopping was in full swing across the US. The system now spiked every day to its maximum capacity, likely due to open refrigerated display case doors, unprecedented re-stocking and pull-down loads. The situation leaves no margin for failure of these critical systems!

One can see the stress on the compressor rack as ambient temperature crept slightly and panic shopping was in full swing across the US. The system now spiked every day to its maximum capacity, likely due to open refrigerated display case doors, unprecedented re-stocking and pull-down loads. The situation leaves no margin for failure of these critical systems!

Preventing System Failure by Identifying Abnormal Operation

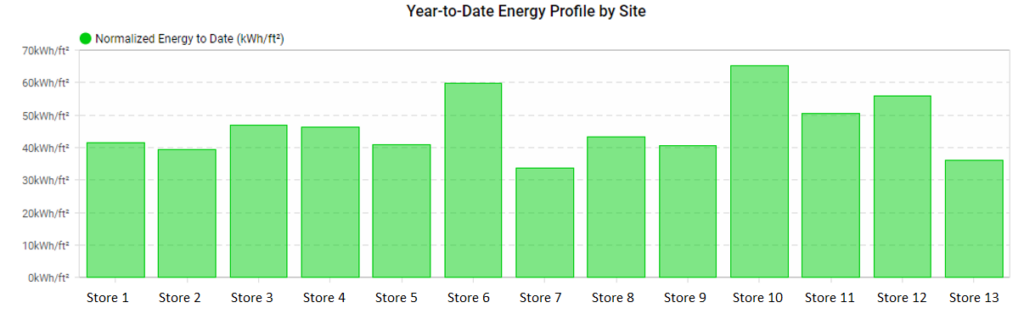

Using the same tools, we can monitor the energy use of each store and identify areas for potential improvement. Below you can see the Energy Use Intensity (EUI) for a group of grocery stores. The EUI is simply the energy use, normalized by square footage. It allows you to identify stores using more energy than others. Of course other factors can introduce variability such as location, weather, or specific end-use loads, like a store that includes a rotisserie versus one that doesn’t. The information is nearly always valuable and can identify potential problems or equipment nearing failure.

One of the best features of kW Link, especially given the pandemic, is its ability to connect to refrigeration systems without ever setting foot in your store. It just needs a VPN connection from your supermarket’s IT department to the store’s energy management systems (EMS). It is a service which provides immediate value to supermarkets by ensuring product and refrigeration system integrity.

One of the best features of kW Link, especially given the pandemic, is its ability to connect to refrigeration systems without ever setting foot in your store. It just needs a VPN connection from your supermarket’s IT department to the store’s energy management systems (EMS). It is a service which provides immediate value to supermarkets by ensuring product and refrigeration system integrity.

Next Steps for Protecting Refrigerated Display Cases and Compressors

Now more than ever, it is critical to take proactive measures to ensure reliable operation of supermarket refrigeration systems. If your supermarket or grocery store chain would like better visibility of its case temperatures, system operation, and smart alarms for notifications of problems before they become catastrophic, all while saving you money, contact us anytime.