Trust, but verify. Seems reasonable, but sometimes in commissioning I think ‘always verify’ is a better phrase.

Investigation is key in retro-commissioning

We were completing a retro-commissioning project on community college building in Southern California and noticed something off in the trend data. The economizer on two air handlers did not seem to be functioning optimally. We suspected the dampers were not fully opening or closing.

We asked the controls contractor (prime) to investigate. They asked their mechanical sub-contractor to check the dampers and make any needed adjustments. After this was completed, I got the following email that indicated it was taken care of.

Air handling unit’s economizer problem fixed?

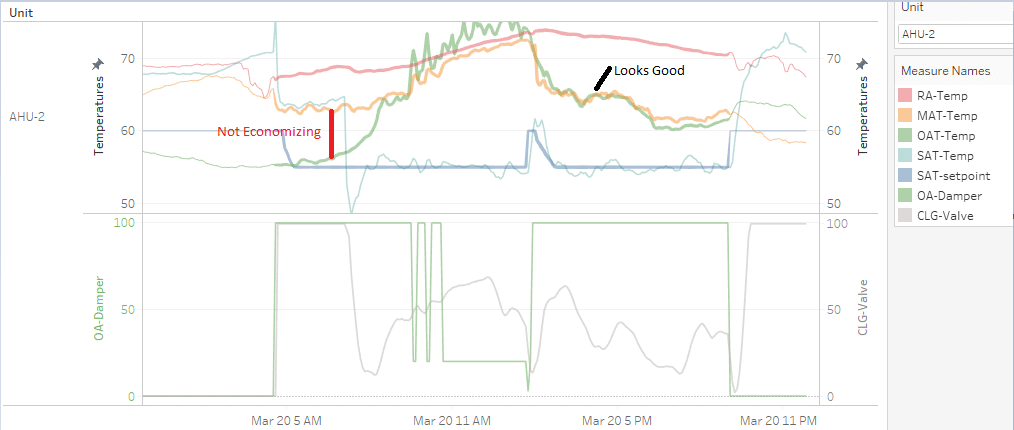

I had access to trend data, so I took a look to verify the economizer performance. The following trend data graphs from air handling unit 2 (AHU-2) and show an adjustment to proper economizer performance during the day on March 20th.

AHU-2 economizer performance. Top graph: The blue line (SAT – supply air temperature setpoint) is the temperature we want from the AHU. We want the orange line (MAT – Mixed air temperature) to be as close as possible to the blue line; we can choose from either the red line (RAT – return air temperature) or the green line (OAT – outside air temperature). So during cooling season, the orange line should track the lower of the green and red lines. Bottom graph: the thin green line shows the outside air damper position (%) and the thin grey line shows the cooling valve position (%).

You can see in the early morning hours, the unit was not economizing: the dampers were 100% open (bottom graph, green line), but the mixed air temp (top graph, orange line) was in between the outside air temp (top graph, green line) and the return air temp (top graph, red line). It should have been tracking cooler outside air.

You can then see by afternoon, the mixed air temp was tracking the lower of the two.

For AHU-1, the data shown in the graph below still showed a problem.

AHU-1 economizer performance

The afternoon data shows that the mixed air (orange line) is actually tracking closer to the return air (red line) than it was in the morning. The damper position was correctly at 100% open (bottom graph) but the temperature is not tracking the outside air temp.

Based on this data, we knew this unit was either not repaired, or something else is going on. Since the data shows that it should be working. Issues like these require a physical inspection.

Problem found

What we found on site was not one, but two, issues.

First, we found that the damper control was accidentally left in ‘Hand’ mode. Thus, it was not responding to the control signal from the building automation system (BAS).

Damper controls

Second, we found that the control wire to the actuator was left disconnected.

Actuator control wires

Issues like these are not uncommon during energy projects. People make mistakes which is why commissioning systems is essential for reliable and optimized building operation. So, please double check those contractor “adjustments”! Don’t just trust, always verify. If you would like to discuss retro-commissioning or optimizing your building or portfolio’s energy use, contact us anytime.

Another Note: Mixed air temperature sensors can be tricky and sometimes not an accurate representation of the true temperature. It depends on where the sensor is located, what type of sensor it is, and how mixed the air streams are; it’s a good idea to visually verify all these things when working with economizer data. We always recommend an averaging sensor that is strung in front of the air filter bank.

Like this post? Share it on LinkedIn.